Mineral Processing

Services and Field of Expertise for Operations

For Concentrators

Many different factors can impact concentrator performance and understanding the relationships that link geology, mineralogy, and processing are critical to maximizing plant performance. Investigating mineralogical characteristics of the feed and various process streams are an important factor in achieving operational efficiency.

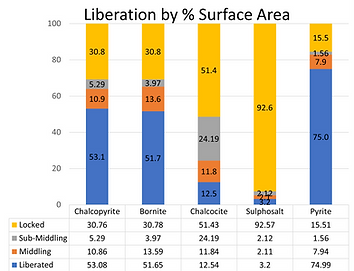

Characterization using TIMA looks at mineral type and abundance, mineral associations, liberation and surface area exposure, elemental deportment and grain size analysis. This information allows us to examine different unit operations and identify areas for improvement.

Targets for study:

-

Identifying target primary and secondary grinds to achieve economic recovery.

-

Investigation into metal losses - liberation, textural, secondary minerals

-

Measure concentrate dilution by gangue

-

Analysis of smelter penalty elements

For Heap Leaching

PMC has developed techniques that allows for mineralogical assessment of heap leach ores even at coarse particles sizes up to 9.5 mm (3/8") on our TIMA Scanning Electron Microscope. With the assessment PMC can quantify the ore minerals and their associations with leachable and non-leachable gangue providing a complete picture of the mineral relationship in the coarsely crushed rock.

The ability for leaching is dependent on the porosity and permeability so PMC also offers Dye Penetration studies. Dye penetration studies utilize standard leach solutions doped with a fluorescent dye during column leaching tests, timed interval photographs under ultraviolet light determine the degree of fluid ingress into coarse fragments. Quantification of the ingress of solution is compared to a database of other rock types from heap leach operations

Compared to Diagnostic or Sequential Leaching - Mineralogy has less cost, requires less sample, while providing more detailed information.

Monthly Mineralogy Profile

Services provided to operations for weekly/monthly mineralogical analysis of various process streams such as Plant Feed, Intermediate Products, Final Concentrate and Final Tail. Performance trends are best explained with on going mineralogical analysis of the various circuit streams and their value to ongoing operations.